Just How to Determine Common Repair Problems in Stretch Wrap Machines and When to Look For Specialist Assistance

Stretch Wrap devices are important for effective packaging procedures. Nevertheless, they can experience numerous issues that impede efficiency. Operators has to be watchful in recognizing signs of malfunction, such as inconsistent film stress or uncommon sounds. Recognizing these typical repair service issues is vital. Understanding when to seek professional aid can make a substantial distinction. The nuances of troubleshooting and upkeep deserve exploring further.

Comprehending the Fundamentals of Stretch Wrap Machines

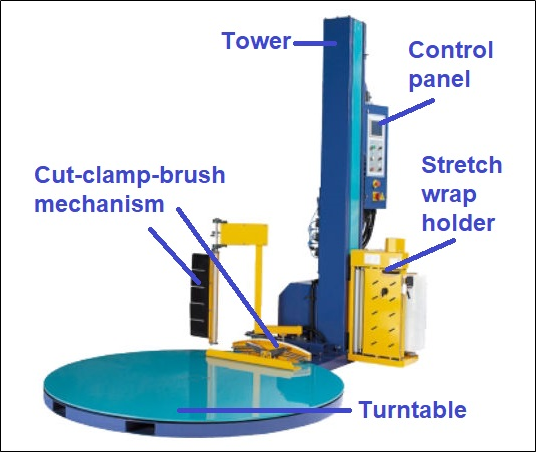

Stretch Wrap makers are vital tools in the product packaging market, created to firmly encapsulate products for storage and transport. These devices use stretch film, which follows itself, producing a tight and protective layer around products. Typically, they can be found in numerous kinds, consisting of handbook, semi-automatic, and completely automatic versions, satisfying varied production requirements. The operation of a stretch Wrap equipment includes feeding the film around the product, using stress, and sealing the Wrap, making certain that goods continue to be steady throughout transit.Key parts of these equipments include the film carriage, turntable, and control panel, each playing a vital duty in the wrapping process. Performance is better enhanced by flexible setups that enable customers to tailor the stress and number of wraps. Understanding these basics aids operators make best use of the equipment's performance, making certain optimal packaging top quality and reducing the threat of item damage throughout handling or delivery.

Usual Concerns With Stretch Wrap Machines

Product packaging efficiency can be considerably jeopardized by typical problems that occur with stretch Wrap makers. One prevalent trouble is inconsistent film stress, which can cause inadequate load stablizing and boosted product damages throughout transport. Additionally, movie damage often takes place, disrupting the covering process and triggering delays in operations. An additional problem is the inappropriate alignment of rolls, which can result in uneven covering and wastage of materials.Malfunctions in the control panel may likewise hinder performance, making it hard to monitor or readjust settings efficiency. Electrical problems, such as malfunctioning electrical wiring, can even more add to operational inefficiencies. Normal upkeep can aid reduce much of these issues, making sure the device operates efficiently. However, recognizing these typical concerns is essential for drivers, as timely treatment can avoid extra pricey repair work and considerable malfunctions.

Signs Your Stretch Wrap Maker Demands Repair

When a stretch Wrap maker displays uncommon sounds during operation, it may suggest underlying mechanical issues. Additionally, inconsistent film stress and constant downtime can even more signify that the device needs prompt attention. Acknowledging these indications early can assist protect against costly repair services and ensure peak efficiency.

Uncommon Noises During Operation

Unusual noises during operation often signal underlying concerns with stretch Wrap equipments that require prompt focus. These sounds may include grinding, squeaking, or clanking, which can show wear and tear on parts such as bearings, motors, or equipments. It may be struggling with imbalance or insufficient lubrication if the device produces unanticipated sounds. Ignoring these audio cues can result in additional damage and pricey repair work. Operators ought to conduct normal assessments to determine and deal with the resource of the sound without delay. Consulting the machine's guidebook can supply certain guidelines for upkeep and troubleshooting. If the issue continues after basic checks, looking for professional aid is advisable to assure the device's longevity and peak efficiency.

Inconsistent Film Stress

Inconsistent film stress can greatly affect the efficiency of stretch Wrap makers, bring about substandard lots stability and potential product damages. This concern often shows up as uneven covers, where particular locations of the load are securely secured while others hang. Operators may observe that the stretch film is either under-stretched or over-stretched, influencing its capacity to comply with the tons. Furthermore, there may be noticeable indicators of changing or slippage throughout transport, indicating that the movie is not giving sufficient support. Such disparities can arise from damaged components, incorrect calibration, or malfunctioning sensing units. Dealing with these problems without delay is crucial to assure peak machine performance and to stop further complications that could arise from inadequate wrapping.

Constant Downtime Issues

Regular downtime issues can signal that a stretch Wrap machine requires immediate fixing. These interruptions often indicate underlying mechanical failings or system breakdowns. Operators might see increased regularity of jams, which disrupt the covering procedure and impede efficiency. Uncommon noises throughout procedure can likewise function as red flags, suggesting that elements may be misaligned or used out. Furthermore, irregular film application can result in insufficient tons protection, prompting further functional hold-ups. Disregarding these signs and symptoms may cause much more extreme damages and pricey fixings. It is essential for operators to monitor their equipments carefully and deal with any indicators of malfunction without delay, making certain effective procedure and reducing downtime in the long run. Looking for specialist help may be necessary for complicated concerns.

Fixing Minor Problems

Fixing small issues in stretch Wrap machines requires a methodical technique to identify and deal with problems successfully. Operators needs to start by checking the power supply and guaranteeing all connections are safe and secure. If the equipment does not start, validating the circuit breakers and merges can commonly disclose simple electrical issues. stretch wrap machine repair near me.Next, evaluating the stretch Wrap film for appropriate placement is essential. Misalignment can cause irregular covering and might require modification of the film rolls. Furthermore, drivers need to keep track of the stress setups; inaccurate stress may cause poor Wrap quality.Routine upkeep, such as cleansing the rollers and guaranteeing they are complimentary from particles, can also stop minor issues from intensifying. Maintaining an eye on the device's performance can help in identifying patterns that suggest underlying problems. By resolving these little browse around this web-site problems quickly, operators can keep peak capability and stay clear of click over here now larger break downs

When to Contact a Specialist

Operators might discover themselves faced with problems that prolong beyond small adjustments and routine upkeep. In such situations, recognizing the ideal moment to call in a specialist becomes vital. It may suggest a deeper electrical or mechanical fault if the stretch Wrap equipment continually stops working to operate correctly in spite of fixing efforts. Additionally, unusual noises, relentless error messages, or failure to Wrap tons firmly are indicators that experience is needed.Furthermore, if the maker experiences regular break downs or if components are damaged, an expert's intervention is essential to protect against more issues. Operators should likewise consider getting assistance when not familiar with certain repair work click for info methods or when safety and security dangers exist. Eventually, prompt expert support can not just solve complex problems yet additionally prevent expensive downtime and warranty optimal efficiency of the stretch Wrap maker.

Preventative Upkeep Tips for Stretch Wrap Machines

Regularly Asked Concerns

What Is the Typical Life-span of a Stretch Wrap Equipment?

Can I Make Use Of Various Types of Stretch Movie on My Machine?

Different kinds of stretch film can be utilized on a device, yet compatibility and efficiency may vary - stretch wrap machine repair near me. It's vital to consult the machine specs and maker standards to ensure the most effective outcomes and stop prospective problems

How Can I Enhance the Effectiveness of My Stretch Wrap Device?

To improve stretch Wrap device effectiveness, regular upkeep, optimal movie stress settings, proper placement, and worker training are crucial. In addition, minimizing and upgrading components downtime through reliable process can greatly boost general performance and outcome.

Exist Any Specific Brands Recognized for Reliability?

Several brand names are recognized for their integrity in stretch Wrap devices, including Signode, Lantech, and Aetna. Customers often applaud these producers for their sturdiness, performance uniformity, and solid client assistance, improving overall operational efficiency.

What Is the Price Variety for Professional Repair Works on Stretch Wrap Machines?

The cost array for expert fixings on stretch Wrap machines differs significantly, generally in between $150 to $1,500, depending on the complexity of the problem, components called for, and the service technician's experience included in the fixing process. The procedure of a stretch Wrap device includes feeding the movie around the product, applying stress, and sealing the Wrap, making sure that goods stay secure throughout transit.Key elements of these machines include the movie control, carriage, and turntable panel, each playing an important function in the wrapping procedure. Inconsistent movie stress can greatly impact the effectiveness of stretch Wrap devices, leading to below average lots stability and possible item damages. Frequent downtime issues can indicate that a stretch Wrap maker calls for immediate repair work. The ordinary life expectancy of a stretch Wrap equipment typically varies from 5 to 15 years, depending on usage, upkeep, and the top quality of the equipment. To improve stretch Wrap maker performance, regular maintenance, optimal movie stress setups, proper positioning, and worker training are necessary.